Custom Plastic Pallets

for Your Workflow

Design Your Perfect Pallet at Preface Plast: Size, Strength, Style — You Choose.

Design the Perfect

Plastic Pallet — Without Limits

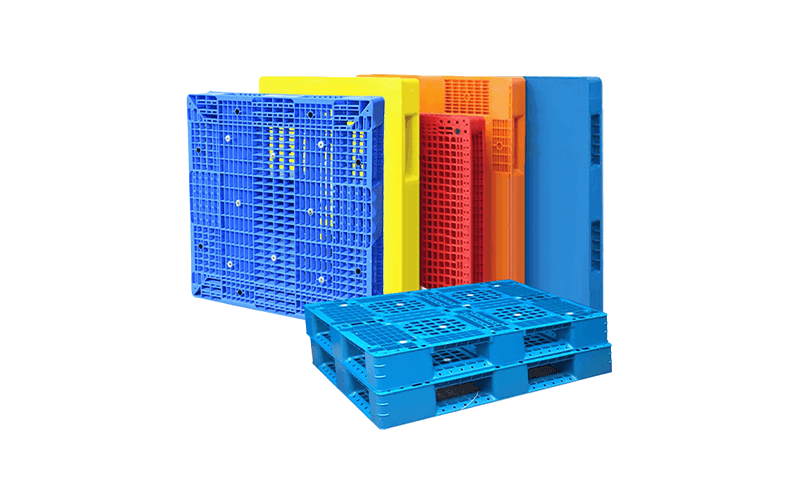

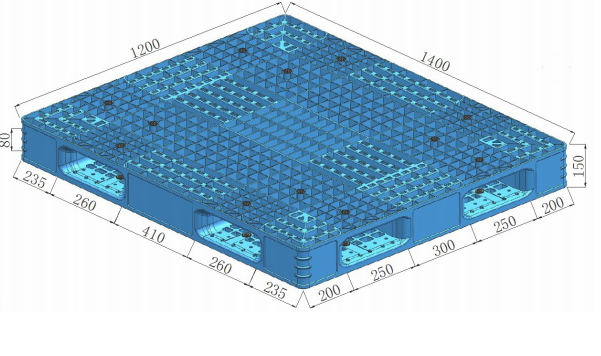

No matter how large, heavy, or uniquely shaped your product is — we design and manufacture plastic pallets tailored precisely to your requirements. Our capabilities include extra-large modular splicing pallets, exact-fit formats that eliminate dead space, and structural reinforcements that ensure load-bearing consistency.

Whether you need better warehouse efficiency, custom dimensions for automated handling, or high-strength designs at competitive pricing, we don’t just offer custom pallets — we optimize your logistics strategy.

Custom Plastic Pallets

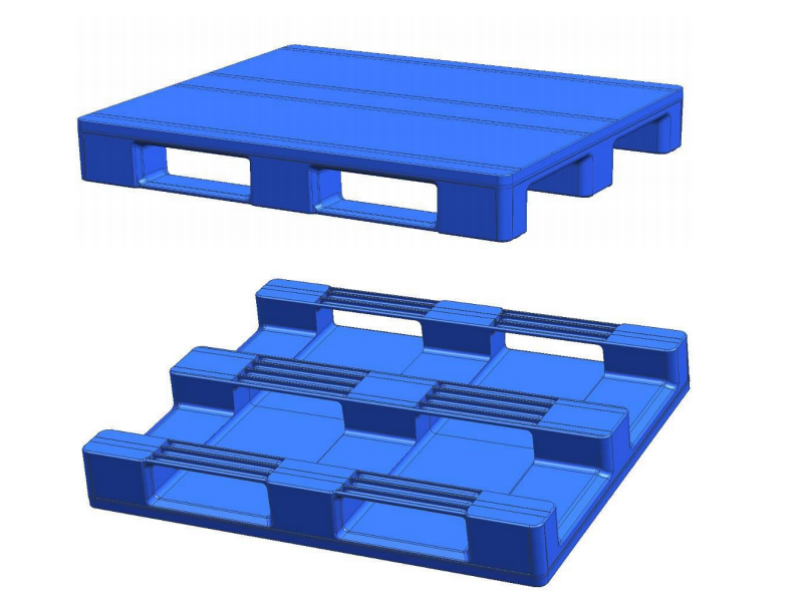

3 Runners

- 800 x 600

- 800 x 800

- 950 x 950

- 1000 x 800

- 1000 x 1000

- 1000 x 1200

- 1100 x 800

- 1200 x 1000

- 1300 x 1300

- 1350 x 1000

- 1400 x 1000

- 1450 x 1150

- 1500 x 1500

- 1600 x 1000

- 1700 x 1200

- 1800 x 1200

6 Runners

- 800 x 600

- 1000 x 1000

- 1100 x 1100

- 1140 x 1140

- 1200 x 800

- 1200 x 1000

- 1200 x 1100

- 1200 x 1200

- 1300 x 880

- 1300 x 1100

- 1300 x 1300

- 1400 x 1200

- 1420 x 1120

- 1420 x 1185

- 1500 x 1185

- 1500 x 1500

9 Legs

- 800 x 600

- 800 x 800

- 900 x 600

- 1000 x 800

- 1000 x 1000

- 1100 x 800

- 1100 x 1100

- 1200 x 600

- 1200 x 800

- 1200 x 1000

- 1200 x 1100

- 1200 x 1200

- 1300 x 1100

- 1400 x 1400

- 1500 x 1300

- 1500 x 1500

Double Side

- 1000 x 800

- 1000 × 1000

- 1100 × 900

- 1100 × 1100

- 1200 × 900

- 1200 × 1000

- 1200 × 1100

- 1200 × 1200

- 1250 × 1120

- 1300 × 1000

- 1300 × 1100

- 1400 × 1100

- 1400 × 1200

- 1400 × 1300

- 1500 × 1200

- 1500 × 1500

Nestable

- 800 x 600

- 800 x 800

- 900 x 900

- 900 x 900

- 1000 x 600

- 1000 x 700

- 1000 x 800

- 1000 x 1000

- 1100 x 800

- 1100 x 900

- 1100 x 1100

- 1150 x 1150

- 1200 x 800

- 1200 x 1000

- 1200 x 1100

- 1200 x 1200

From Design to Delivery — Your Custom Pallet Workflow

Consultation – Understand your industry and requirements

Every successful pallet solution starts with understanding your real-world logistics environment. Our team doesn’t offer generic advice—we listen.

From cold-chain warehouses to high-bay automated systems, we assess your stacking height, forklift type, load variation, and hygiene requirements to recommend the exact pallet structure and material configuration that will work best.

You talk. We translate it into engineering.

Design Proposal – CAD drawings and load specs within 48h

Within 48 hours, you’ll receive a fully tailored design pack—including CAD drawings, load-bearing specifications, and plastic formulation guidance.

Need ESD protection? Special rim guards? Hollow leg structure? We integrate all technical requirements upfront. Our goal is simple: get you from idea to verified plan without delay.

Mold Adjustment / Fabrication – Optional for unique sizing

For non-standard sizes or special-function pallets, we offer in-house mold adjustment and modular tooling fabrication. From custom-fit reversible pallets for beverage crates to one-way export pallets with weight-saving design—we help you minimize tooling costs while maintaining precision.

Backed by years of mold optimization experience, we don’t just “customize”—we engineer for scale.

Sample Testing – Load test, drop test, compatibility check

Before production, we put every concept through real-world testing: stacking simulation, racking compatibility, edge drop resistance, and forklift clearance validation.

Our internal QC team documents it all. And yes—we send physical samples via DHL, air, or sea, so your team can test performance on-site before approving the final batch. We build trust before we build at scale.

Production & Delivery – 15–20 days depending on quantity

Custom pallets are produced in our own ISO-audited factory, ensuring full control over materials, tolerance, and delivery timeline. Most bulk orders ship within 15–20 days, supported by optional container load planning, mixed SKUs packing, and global freight solutions.

Whether you’re buying 500 or 5,000 units, we deliver quality, consistency, and commitment—on your schedule.

FAQ:

Normally 300 pcs for color/logo; 5000 pcs for mold change.

Yes, we offer internal steel reinforcement options for rackable pallets(including 3 runners, 6 runners, double face base).

15–20 working days for most custom orders.

Absolutely. We encourage pre-order testing and provide free pre-production samples—you only need to cover the shipping cost.

Yes. Our engineering team can provide size recommendations based on your racking, forklift type, and automated system specs. We offer CAD support to ensure perfect compatibility before mold finalization.

Absolutely. We offer multiple color options for inventory coding, and materials including virgin HDPE, recycled HDPE, and ESD-safe compounds depending on your application and compliance needs.

Yes, we provide stretch-wrapped or strapped bundles with optimized pallet-in-pallet nesting if applicable. We also offer mixed-model container loading and packing layout designs to reduce freight costs.

Minor structural or cosmetic adjustments are welcome before mass production. We'll revalidate critical dimensions and function points with you to ensure the final version meets your expectations.