Built for industrial precision, our full perimeter plastic pallets with 6 runners offer exceptional load stability, forklift access from all sides, and seamless rack-to-floor versatility. Trusted for heavy duty use in racking, floor handling, and stacking scenarios across manufacturing and logistics sectors.

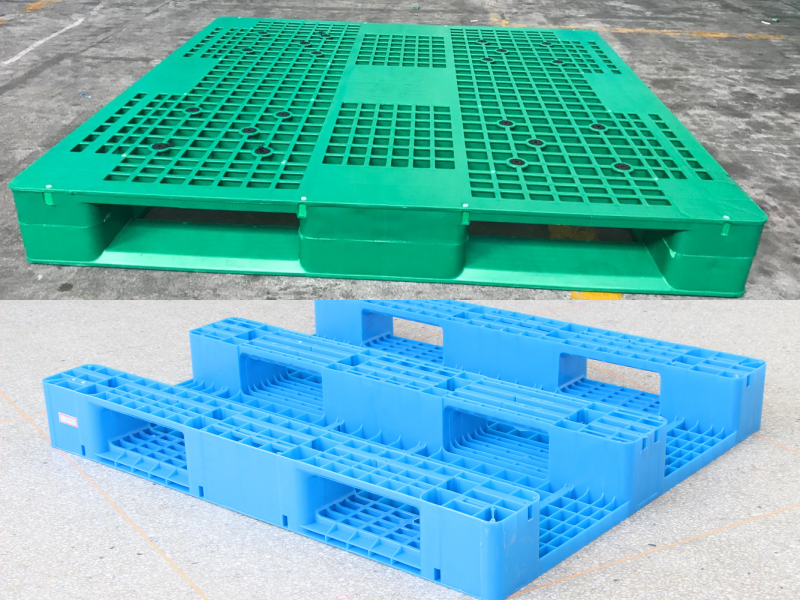

Usage: Rackable, stackable, and suitable for floor use with 4-way forklift entry

Manufacturing Process: Injection molding, welding, and assembly available

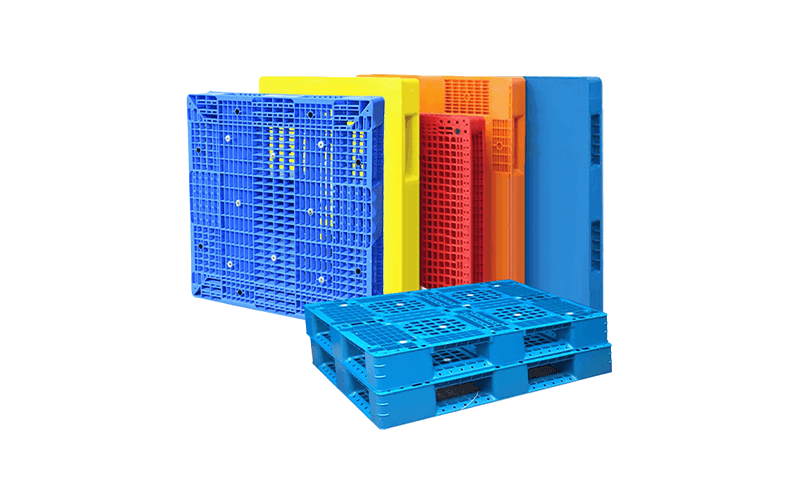

Surface Options: Flat top, open deck, or ventilated grid surface

Load Capacity: Supports heavy duty static and dynamic loads (customizable per model)

Solid top, ventilated grid, and hybrid decks are offered to match distinct handling environments. Whether minimizing moisture retention or supporting delicate packaging, each surface style is engineered for practical fit across food, pharma, and cold-chain workflows.

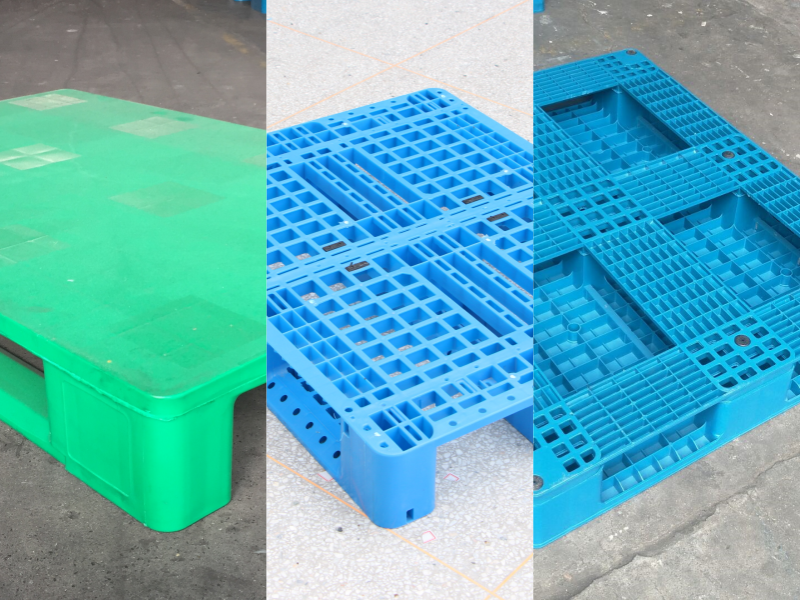

The fully enclosed 6-runner base ensures uniform bottom support across racks and stacked loads. This structure avoids point stress and improves beam contact, making it ideal for high-bay storage and long-term vertical stacking scenarios.

Designed with sloped guides on all sides, these pallets simplify forklift and pallet jack entry—even in tight warehouse lanes. This detail improves maneuverability and reduces collision risk during high-frequency ground-level operations.

To enhance stacking safety, both solid and grid deck options can be equipped with anti-slip inserts. This feature helps reduce slippage during handling or transport, especially under vibration or in tall stacking operations without straps.

Units are formed either by high-pressure injection molding or seamless welds between top deck and base runners. This construction eliminates weak joints, improving impact resistance and dimensional consistency over thousands of cycles.

Corner zones are structurally reinforced with molded-in ribs that absorb shock during fork entry or loading. This prevents edge cracking and helps preserve pallet integrity across demanding logistics and export cycles.

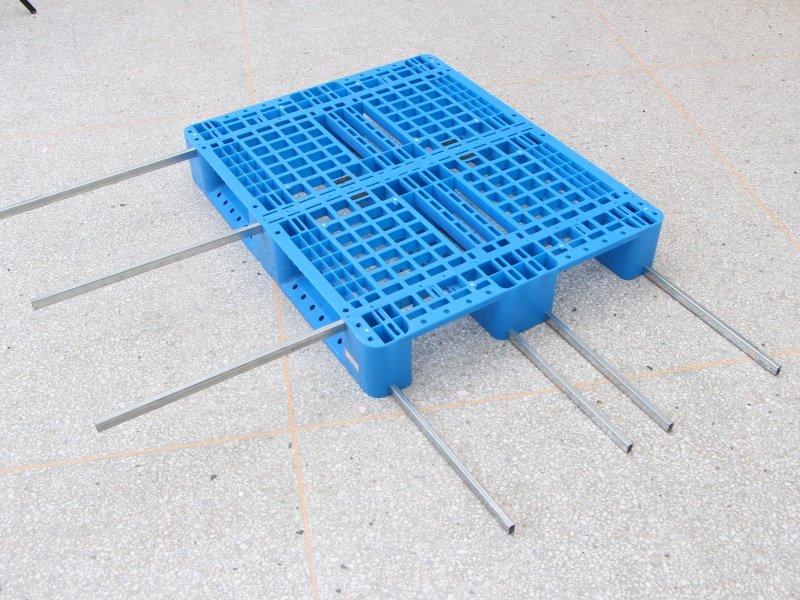

For operations requiring higher racking loads or reduced deflection, steel reinforcement slots are built into the core. Reinforced pallets maintain flatness under 1.5–2T loads and perform reliably in automated storage systems.

Produced using non-porous HDPE or PP, the surface resists water retention, chemical corrosion, and microbial buildup. Easy to rinse and quick to dry, it fits hygiene-sensitive industries and reusable supply chains with strict sanitation standards.

Brand identifiers such as engraved logos, region-specific colors, and RFID slots can be integrated during molding. These options support product traceability, reduce pick errors, and align the pallets with enterprise-level logistics systems.

Every full perimeter plastic pallet with 6 runners is built not only for rack stability—but for measurable performance under extreme warehouse conditions. Before any pallet leaves our facility, it undergoes load, stress, and durability testing specific to its six-runner structure to ensure reliable use in stacking, racking, and floor operations.

Our 6-runner-specific tests include:

Static Load Test

Verifies pallet strength under 6T weight for long-term rack or floor use.

Dynamic Load Test

Confirms stability during forklift handling under full payload.

Racking Deflection Check

Measures runner contact and flex across beam supports.

Corner Impact Test

Tests reinforced corners against edge strikes and forklift impact.

Steel Reinforcement Check

Inspects embedded tubes for secure fit and balanced load support.

Beverage, Canned Goods & Bottling Plants

Frozen Food Warehousing & Cold Chain Transport

Pharmaceutical Supply & Cleanroom Packaging

FMCG & High-Throughput Retail Distribution

Automotive Parts, Engines & Component Logistics

Molded Metal Products & Sheet Material Storage

Assembly Line Transfer in Industrial Facilities

Export Shipping & Container-Based Distribution

Resin, Powder & Bulk Chemical Handling

Large Volume Paper Rolls & Printing Materials

National Logistics Providers & Distribution Hubs

Government Procurement & Centralized Warehousing

Agricultural Input, Feed & Fertilizer Transport

Integrated steel reinforcement for heavy racking loads

Optional anti-slip rubber inserts on deck surface

Logo embossing or engraving for brand identification

Custom color options for zone or SKU management

RFID tag and barcode slot integration for traceability

Drain holes or sealed base structure upon request

Dimension adjustment for system compatibility

Material selection: virgin HDPE, PP, or blended resin

Surface texture customization (matte, semi-gloss, anti-scratch)

Reinforced corner ribs or chamfered entry design

Custom stacking stops or locator pins for automation use

All full-perimeter pallets are injection-molded using dedicated steel tooling with ±0.5mm dimensional tolerance. Integrated steel tube slots and multi-rib runner reinforcements ensure minimal deflection under 1,500–2,000kg rack loads. Batch consistency is validated through corner load tests and digital runner depth inspection across every lot.

With 5 automated injection lines and dual-day mold cycles, we produce up to 100,000 pallets monthly. Custom fork entry styles, non-standard dimensions, and selective steel bar placement can be tailored per project. Dedicated engineers assist with drawing validation, especially for automation or export-specific specs.

Each model passes 6T static load, 1.5T dynamic, and 1.2T racking deflection checks, using certified weight blocks and calibrated jigs. Full traceability is supported by QR-coded batch records. Our multilingual export team handles technical documents, container loading maps, and post-sale issue resolution within 24h.

For existing models, MOQ starts from 200–300 pieces. For mold-customized pallets, the minimum order is 5,000 pieces due to tooling and production setup.

Yes. Our full perimeter pallets meet international shipping standards and are widely used for global exports, container loading, and overseas warehousing.

Many of our hundreds of pallet models are designed for AGV, conveyor, and racking systems. We also support structural customization to match your automation requirements.

Alibaba Trade Assurance, T/T, L/C, PayPal, Western Union, or other agreed terms are available depending on the transaction volume.

For standard models, lead time is typically 15–20 working days. Custom structures or large-volume orders may vary depending on the configuration.

Yes, samples are available for evaluation. We offer them free of charge; you only need to cover the shipping cost.

Of course. Please contact us through the inquiry form or listed communication channels to receive our latest product manual and spec sheets.

Yes. Selected full-perimeter models support built-in steel tube channels, ideal for high-racking and heavy-duty use. Steel configurations can be customized per load specs.

Absolutely. We support mixed-loading and split-container shipments, making it easier to test multiple sizes or fulfill regional stocking strategies.

Yes. Test reports for static, dynamic, and racking loads are available. We also support third-party SGS/ISO testing upon request.

+86 131 7320 7232

sales29@cnplasticpallet.com

Optics Valley Software Park, Huangdao District, Qingdao City, Shandong Province, China

With over 24 years of manufacturing experience, Preface deliver over 500,000 plastic pallets annually to 40+ countries. Certified by ISO 9001 and SGS.

With over 24 years of manufacturing experience, Preface deliver over 500,000 plastic pallets annually to 40+ countries. Certified by ISO 9001 and SGS.

Contact Us Online

Receive a response within one business day. Please check your emails at “sales29@cnplasticpallet.com” to ensure timely and efficient communication.