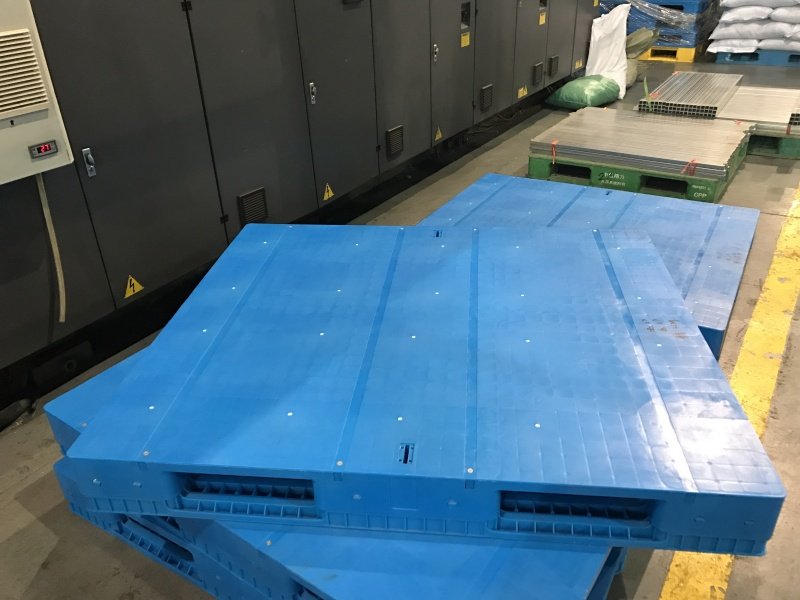

Our hygienic plastic pallets are built for food, pharmaceutical, and cleanroom logistics—combining FDA-approved, solid-deck surfaces with durable HDPE materials. Designed for strict sanitary conditions, they are ideal as food grade pallets, rackable plastic pallets, or heavy duty industrial pallets.

Material: 100% virgin HDPE or PP, food grade certified

Deck Type: Solid surface, easy to clean, no water retention

Certification: FDA, EU 10/2011, GMP/HACCP compatible

Load Capacity: Up to 1500/2000kg dynamic, 6000kg static, 1000/1500kg rack

Design Options: One-piece, rackable, 4-way entry, anti-slip

Seamless solid deck prevents water absorption and bacterial growth.

Optional anti-slip strips and edge guards keep loads stable on racks and conveyors.

3-runner base design supports racking, block stacking, and four-way forklift access.

Available in injection molding, hot plate welding, and panel assembly.

Made from food-grade HDPE or PP, resistant to moisture, insects, and chemicals.

Fully waterproof and easy to clean, compatible with pressure washers.

Suitable for -30°C to +40°C environments, ideal for cold chain logistics.

Heavy-duty construction ensures long-term use and high load performance.

Supports automated handling and tracking, including optional RFID integration.

Crack-free, smooth surface meets HACCP and GMP cleanroom standards.

Custom dimensions available to fit regional logistics standards or production workflows.

Custom colors support hygiene zoning, material flow coding, and HACCP compliance.

Optional fully enclosed flow channels eliminate exposure to contaminants and residue.

Optional reinforced steel pipes (minimum 4) improve structural rigidity for heavy-duty use.

Logo marking and serial codes can be added for pallet-level traceability.

Surface options include smooth, textured, or micro-embossed finishes to suit cleaning methods.

Integration of RFID tags or temperature sensors enables smart cold chain tracking.

Add-on anti-slip strips improve safety on conveyors and sloped surfaces.

Runner configurations can be customized for compatibility with AGVs or high racks.

Optional sealed edges and beveled corners enhance cleanability and operator safety.

FDA (21 CFR 177.1520)

Raw materials comply with U.S. FDA regulations for plastic materials in direct food contact.

EU 10/2011

Pallet surfaces meet European Union standards for plastics intended to contact foodstuffs.

GMP & HACCP Compatibility

Seamless, non-absorbent design supports contamination control in certified clean zones.

ISO 22000 / ISO 9001

Manufactured under certified systems ensuring consistent food safety and quality control.

REACH & RoHS Compliance

All materials are free from restricted substances, ensuring safe use in sensitive environments.

Custom Documentation Support

Material traceability and compliance documents available on request for audits.

Yes. Made from food-grade HDPE or PP, our pallets comply with FDA 21 CFR 177.1520 and EU 10/2011. The solid, seamless deck prevents fluid absorption and bacteria buildup—ideal for cleanrooms and open-contact zones.

They support pressure washing, steam cleaning, and manual disinfection. Sealed surfaces drain fast, and optional micro-textures reduce cleaning agent use. Compatible with VHP sterilization and alcohol-based sanitizers in pharma zones.

Plastic pallets are lighter, rust-free, and quieter than steel. They offer equal hygiene compliance at lower cost, suit cold chain use, and allow easier RFID or color coding. Steel is preferred only in extreme heat zones.

Most models fit ASRS when using standard sizes like 1200×1000mm or 1200×800mm. We offer uniform runners, anti-slip options, and deformation control, but final fit depends on your system. Drawings and tests available on request.

Yes. Our pallets are made from non-wood materials and meet ISPM 15 exemption requirements. They are accepted for global shipments without fumigation—ideal for food and pharma exports to the U.S., EU, Japan, and more.

Most pallets last 5–10 years with regular handling. Reinforced models with steel pipes and impact-resistant HDPE withstand thousands of cycles without cracks or warping, even in high-traffic industrial environments.

Yes. We provide dimensional tolerance data, deformation test results, and mock-fit verification based on your specs. This ensures safe use with ASRS, shuttle systems, and robotic forklifts before mass deployment.

Standard sizes ship in 7–15 business days. For custom specs like colors, steel inserts, or RFID tags, lead time is usually 2–4 weeks, depending on volume and tooling. Compliance documents are available with all custom orders. For more details on customization options, please visit our Custom Service page.

+86 131 7320 7232

sales29@cnplasticpallet.com

Optics Valley Software Park, Huangdao District, Qingdao City, Shandong Province, China

With over 24 years of manufacturing experience, Preface deliver over 500,000 plastic pallets annually to 40+ countries. Certified by ISO 9001 and SGS.

With over 24 years of manufacturing experience, Preface deliver over 500,000 plastic pallets annually to 40+ countries. Certified by ISO 9001 and SGS.

Contact Us Online

Receive a response within one business day. Please check your emails at “sales29@cnplasticpallet.com” to ensure timely and efficient communication.