As a direct manufacturer of plastic pallets for the printing industry, we offer precision-built pallets for non stop feeder lines and pre-print paper storage. Our designs include ribbed deck plastic pallets, nestable pallets, and flat surface models engineered for smooth paper handling, ground use, and automation system compatibility. We support injection and blow molding processes, custom dimensions, and strict quality certification, with samples and full inspection reports available.

✅ Application: Non-stop printing lines & pre-transfer storage

✅ Use Condition: Suitable for direct ground-level operations

✅ Automation Compatibility: Supports conveyors, feeders, robots

✅ Manufacturing Process: Injection molding

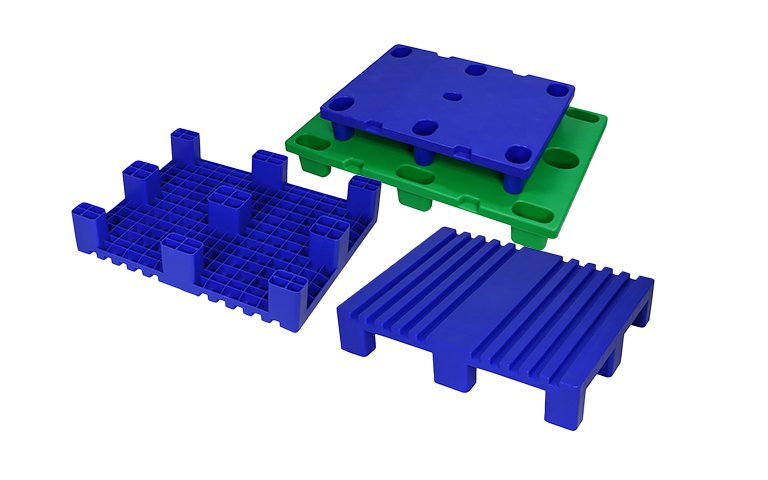

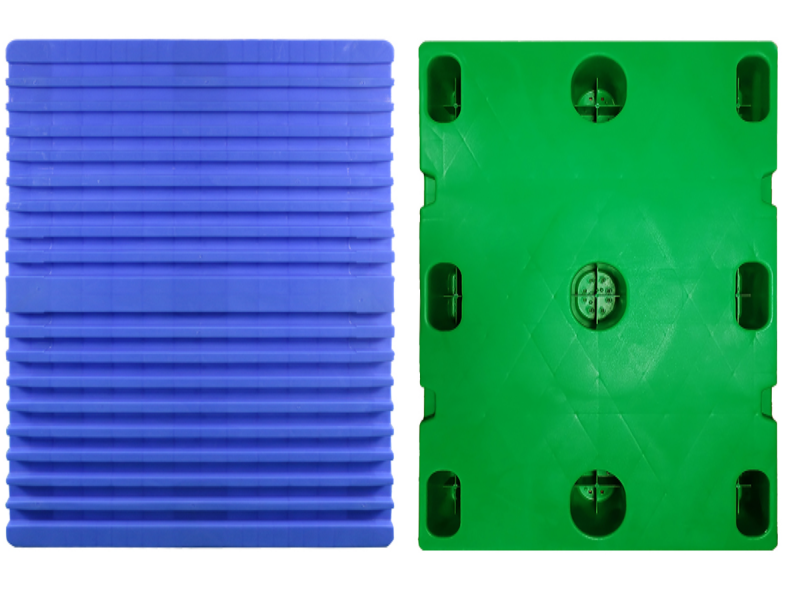

✅ Deck Types: Smooth flat top or ribbed open deck available

Plastic printing pallet is a type of smooth-surface plastic pallet designed to safely support paper stacks, packaging materials, or printed sheets during storage, transport, and pressroom operations.

Made from HDPE or PP, it features options like nestable legs, stackable frames, or four-way forklift access to suit various print shop workflows. Commonly used in commercial printing plants, paper warehouses, packaging workshops, and digital press lines, this pallet prevents edge damage, reduces dust contamination, and keeps sheet stacks stable. For anyone moving paper, think of it as the quiet workhorse that protects every sheet before it hits the press.

We offer flat-deck pallets for paper storage and grooved-top pallets for in-line feeding.Nestable versions can be stacked into each other after use, reducing return freight volume and cutting logistics costs for closed-loop or export operations.

The fully enclosed surface is made of high-density HDPE or PP, ensuring no nails, splinters, or edges that could tear, crease, or mark paper. It's ideal for keeping sheet-fed materials clean, undamaged, and ready for press at any time.

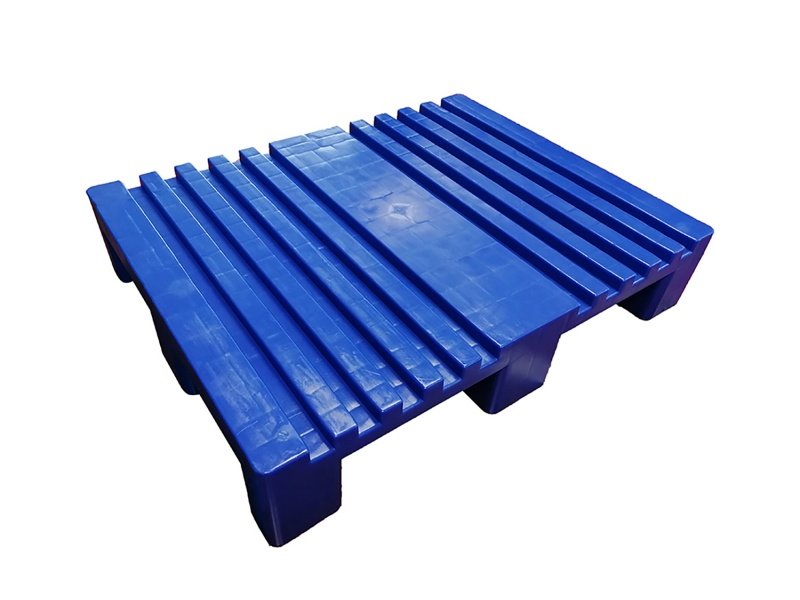

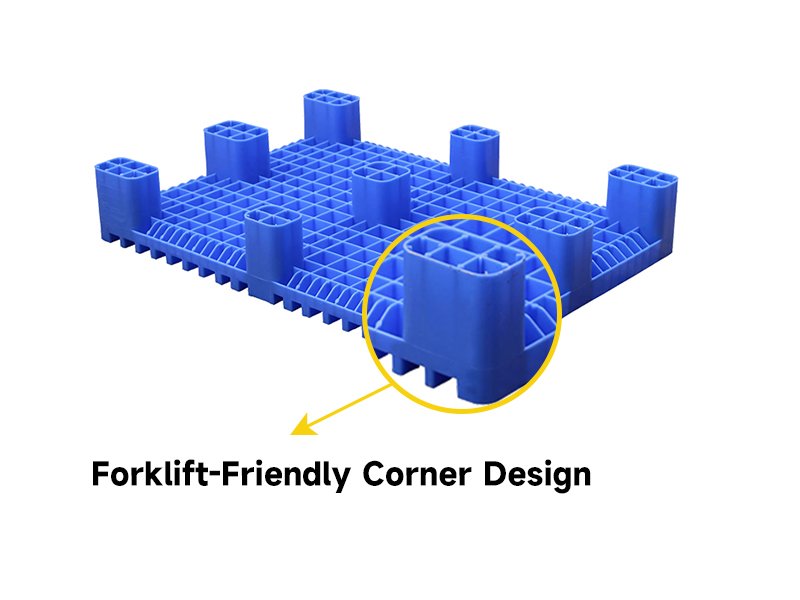

Integrated reinforcement ribs under the deck prevent warping under heavy loads, maintaining surface flatness over time. Rounded forklift entry edges reduce pallet impact and speed up alignment during handling, even in high-speed loading areas.

All pallets feature four-way forklift access for efficient handling. Both types are built with tight tolerances for consistent performance. Grooved-top models integrate with auto-feeders, conveyors, and robots, enabling fully automated, jam-free material flow.

Constructed from durable HDPE/PP, these pallets resist cracking, moisture, and chemical damage. With a lifespan 5–8x longer than wood and no upkeep needed, they cut long-term costs and reduce operational downtime significantly.

We support custom sizing, logo printing, and color coding to match your internal logistics system. Tailored designs ensure full compatibility with your paper specs, helping streamline handling, sorting, and in-factory pallet rotation.

Designed for continuous feeding on offset and digital printers

Grooved surface fits auto-feeders, conveyors, and robotic arms

Prevents paper skewing, improves workflow speed, and supports full automation

Nestable flat pallets store paper stacks before and after printing

Ideal for bindery, cutting, and sorting areas with frequent turnover

Empty pallets can nest to save 60% floor space during idle time

Fully closed deck with no splinters or gaps—ideal for delicate sheets

Available in custom sizes to match your paper dimensions exactly

Widely used for longer-term indoor storage or inter-department transfer

Lightweight pallets suitable for one-way shipments of paper goods

Cost-effective, export-compliant, and free from fumigation requirements

Recommended for overseas printing clients or long-distance transport

Paper-Matched Deck Size

Dimensions tailored to your sheet format—minimizes overhang, prevents edge curling, and improves stacking safety.

Groove Pattern & Depth

Custom groove spacing and channel depth ensure seamless paper feeding with your specific auto-feeder or conveyor system.

Color Coding by Workflow Stage

Choose pallet colors for each department—streamlines visual sorting in pre-press, printing, or packing zones.

Logo or Batch ID Molding

Permanent branding or code embossing on deck surface or legs—ideal for internal tracking or loss prevention.

Anti-Slip Surface Texture

Optional matte or ribbed finish improves grip when handling coated paper or film materials.

Static Load & Wall Thickness

Adjust pallet wall thickness and ribbing based on your required load weight and storage conditions.

Our team replies within 12 hours, based on your sheet size, equipment specs, and load needs. We’ll suggest the best-fit model or custom solution the same day, helping you move forward without delay.

Yes. Physical samples ship within 3–5 days—just cover the freight. We also offer 2D/3D CAD drawings (STEP, DWG, PDF) to verify equipment compatibility before bulk production.

Absolutely. We offer ISO 9001, RoHS, REACH, and SGS load test reports with each order. Dimensional reports and QC records are included to support compliance and export requirements.

Yes. We customize groove depth, spacing, and edge design to fit your auto-feeders, robots, or conveyors, ensuring jam-free, seamless material flow during high-speed printing operations.

Nestable pallets support pre-dispatch storage and help cut purchase costs. They nest tightly when idle, maximizing floor space. Stackable models offer full-base support for heavier internal handling.

Yes. We tailor pallet decks to match different sheet sizes or offer multi-format solutions with guides and textures, helping you reduce SKU count while ensuring safe stacking.

Yes. All pallets meet ISPM 15 standards, requiring no fumigation. We also offer lightweight one-time use pallets ideal for overseas clients and compliant with most export regulations.

Definitely. We support molded-in logos, batch codes, or laser-engraved IDs, making internal tracking easier and helping you prevent pallet loss or mix-ups in complex print logistics.

Our pallets last 5–8 years under regular use, resisting moisture, ink, and deformation. No maintenance is needed, making them a cost-effective, long-term solution for print production lines.

+86 131 7320 7232

sales29@cnplasticpallet.com

Optics Valley Software Park, Huangdao District, Qingdao City, Shandong Province, China

With over 24 years of manufacturing experience, Preface deliver over 500,000 plastic pallets annually to 40+ countries. Certified by ISO 9001 and SGS.

With over 24 years of manufacturing experience, Preface deliver over 500,000 plastic pallets annually to 40+ countries. Certified by ISO 9001 and SGS.

Contact Us Online

Receive a response within one business day. Please check your emails at “sales29@cnplasticpallet.com” to ensure timely and efficient communication.