Built for demanding industrial use, our reversible plastic pallets feature a solid or vented double-sided deck ideal for racking, stacking, or floor storage. Designed for four-way forklift access, they ensure stable load transfer, increased reusability, and reduced wood pallet failures across logistics, manufacturing, and warehouse environments.

✅ Application: Rackable, stackable, and floor-use; 4-way forklift entry

✅ Process: Injection molding, welding, or blow molding

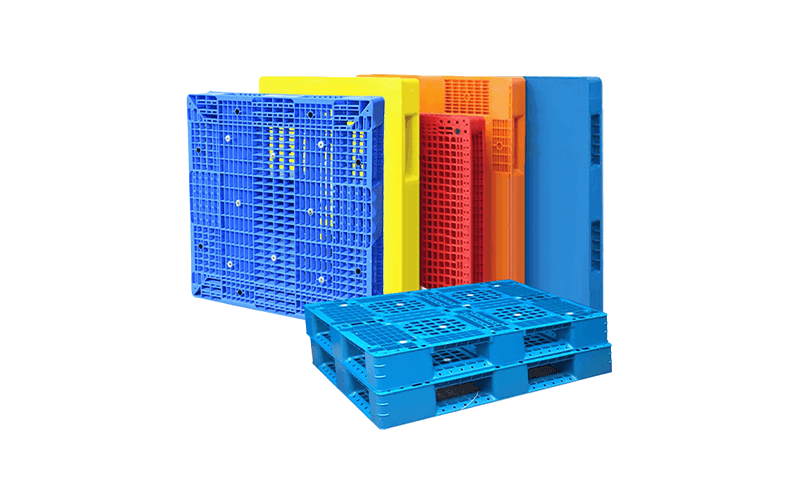

✅ Surface: Solid or vented deck options

✅ MOQ: 200 pcs; supports OEM size and logo

✅ Size & Load: Up to 2040×1260mm; static 6t, dynamic 1.5t

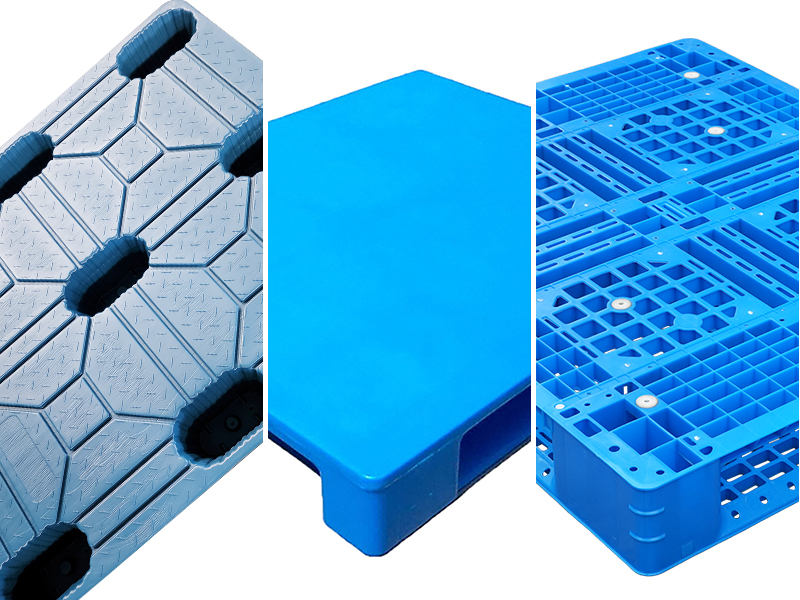

Both sides are fully load-bearing—each pallet handles cargo, ground contact, and racks without flipping. This eliminates orientation errors and improves workflow accuracy and operator safety.

Standard models support 1.5T dynamic / 6T static / 1T racking load. Steel-reinforced versions with 4 pipes offer greater strength and long-term racking stability for high-density warehouse use.

We build for beam racks, drive-in racks, and AS/RS compatibility. Our reversible structure meets automated system standards, enabling two-way flow and faster machine-side alignment.

We manufacture using injection molding, welding, and blow molding, based on usage needs. Blow-molded pallets offer greater wall thickness and impact resistance, ideal for high-load or harsh environments.

Our pallets use high-strength HDPE to withstand daily forklift contact. They hold shape under stress and resist cracking, edge chipping, and deformation in fast-paced, high-turnover facilities.

Fully sealed and debris-free, our pallets stay clean in humid or outdoor settings. No mold, no splinters, and UV stabilizers available—a long-life alternative to wood in demanding conditions.

We offer models with built-in steel reinforcement to handle heavy static loads and vertical stacking. Add up to 4 pipes to maximize shelf performance in cold storage or bulk inventory zones.

Every model supports four-way entry for use with forklifts and hand jacks. Efficient handling across aisles, racks, and conveyors makes loading and unloading faster and safer for all operations.

We offer three top surface types: blow-molded structured decks for heavy-duty use, grid decks for airflow and drainage, and solid decks for hygiene, sanitation, and sealed product contact.

Food & Beverage Processing

Cold Chain & Refrigerated Logistics

Pharmaceuticals & Medical Manufacturing

E-commerce & Retail Distribution

Automotive & Heavy Equipment Parts

Metals, Steel & Sheet Materials Handling

Industrial Manufacturing & Assembly Lines

Export & Cross-Border Trade

Chemical, Coatings & Raw Material Handling

Textiles, Paper & Flexible Packaging

Third-Party Logistics (3PL) & Contract Warehousing

Government & Defense Supply Systems

Agriculture & Fertilizer Warehousing

Automated Storage Systems:

Used in AS/RS systems and conveyor-fed warehouses where both sides of the pallet must be contact-compatible, ensuring seamless direction-neutral pallet flow.

Stacking Operations:

Ideal for high-load stacking of boxed or bagged products, with both pallet sides designed for contact with goods, ground, or upper loads—eliminating flip errors during handling.

Finished Goods Buffer Zones:

Used in outbound lanes where finished products await shipment. Double-sided design supports consistent bottom-top stacking, reducing waiting time and manual corrections.

Export Shipping:

Compliant with ISPM 15-exempt material standards, our pallets are widely used for bulk international shipments that require return handling or multi-directional load access.

We offer full flexibility in size, material, logo printing, QR tracking, color, deck style, anti-slip pads, and reinforcements—tailored for your specific logistics needs.

Our reversible pallets are built for durability and backed by a 3-year warranty. If damage occurs during normal use, we’ll replace it to ensure zero operational loss.

Each pallet undergoes forklift impact, stacking compression, and drop tests to ensure reliable performance across racking, automation, and high-frequency warehouse operations.

Yes. We apply high-precision injection and welding techniques to ensure that both upper and lower decks are structurally identical in thickness, support ribs, and load-bearing surface. Each pallet is tested under reverse pressure to confirm true two-sided usability without deformation.

Yes. Our reversible pallets are designed with full-deck support structures like 6-runner or 3-runner bases, which allow them to rest securely on standard rack beams even without steel reinforcement. For higher static loads or long-term shelf compression, internal steel pipes are optional to enhance rigidity, but not mandatory for racking use.

Yes. Our double-sided pallets feature a flat, closed lower deck with consistent leg spacing, making them compatible with powered rollers, turntables, chain conveyors, and robotic pallet feeders. The base deck maintains uniform contact during motion.

Absolutely. The mirrored panel design with full-length ribbing and anti-slip stops prevents shifting even during vertical compression. We test each design under 3–4x stacking height with dynamic weight to ensure structural integrity in vertical systems.

They solve real operational problems: no flipping needed, no alignment errors, and no delay at machine entry. In systems where pallet orientation can’t be manually controlled—like AS/RS or robotic loading—reversible designs offer complete layout flexibility.

Yes, the mass is higher due to double-deck construction and full reinforcement, but that weight contributes to greater impact resistance, longer life cycles, and stable stacking. For clients using automated handling, the added weight actually enhances control precision.

Yes. For customers requiring higher crash tolerance, thicker outer walls, and heavy-duty outdoor usage, we recommend blow-molded reversible pallets. These are especially popular in beverage, steel, and fertilizer sectors.

Yes. We use virgin or UV-stabilized HDPE with a working temperature of -30°C to +60°C. The structure remains flexible and crack-resistant in frozen storage, making it suitable for meat processing, seafood, and pharma cold chains.

Yes. All models are engineered with four-direction notched legs that allow smooth insertion of manual pallet jacks and front/rear forklifts, even in tight dock environments or elevated platforms.

Definitely. Our pallets are ISPM 15-exempt, fumigation-free, and durable across multiple shipments. Compared with wood, they don’t warp or splinter, and are better suited for cross-border loops or one-way outbound shipments.

Yes. We offer both fully recyclable HDPE and post-consumer recycled blends, depending on your ESG policy. All models meet RoHS/REACH standards, and we provide CO2-reduction data for sustainability reporting.

Yes. We provide free samples of our reversible pallets, including standard or custom models. You only need to cover the shipping cost—there is no charge for the product itself.

Our standard lead time is 7–12 business days, depending on quantity and mold availability. For urgent orders, we offer priority line scheduling and pre-molded stock dispatch within 3–5 days.

For most reversible pallets, the MOQ is 200–300 units per model. For customized logos, colors, or steel tube versions, MOQ may increase slightly due to tooling changeovers.

Yes, if dimensions are compatible. We optimize loading plans to allow multi-model mixed containers, especially for export buyers consolidating SKUs.

Yes. We support SGS, ISO 9001, ISO 14001, REACH, and factory audits. For long-term partners, we also assist with pre-shipment QC coordination or video inspection.

+86 131 7320 7232

sales29@cnplasticpallet.com

Optics Valley Software Park, Huangdao District, Qingdao City, Shandong Province, China

With over 24 years of manufacturing experience, Preface deliver over 500,000 plastic pallets annually to 40+ countries. Certified by ISO 9001 and SGS.

With over 24 years of manufacturing experience, Preface deliver over 500,000 plastic pallets annually to 40+ countries. Certified by ISO 9001 and SGS.

Contact Us Online

Receive a response within one business day. Please check your emails at “sales29@cnplasticpallet.com” to ensure timely and efficient communication.