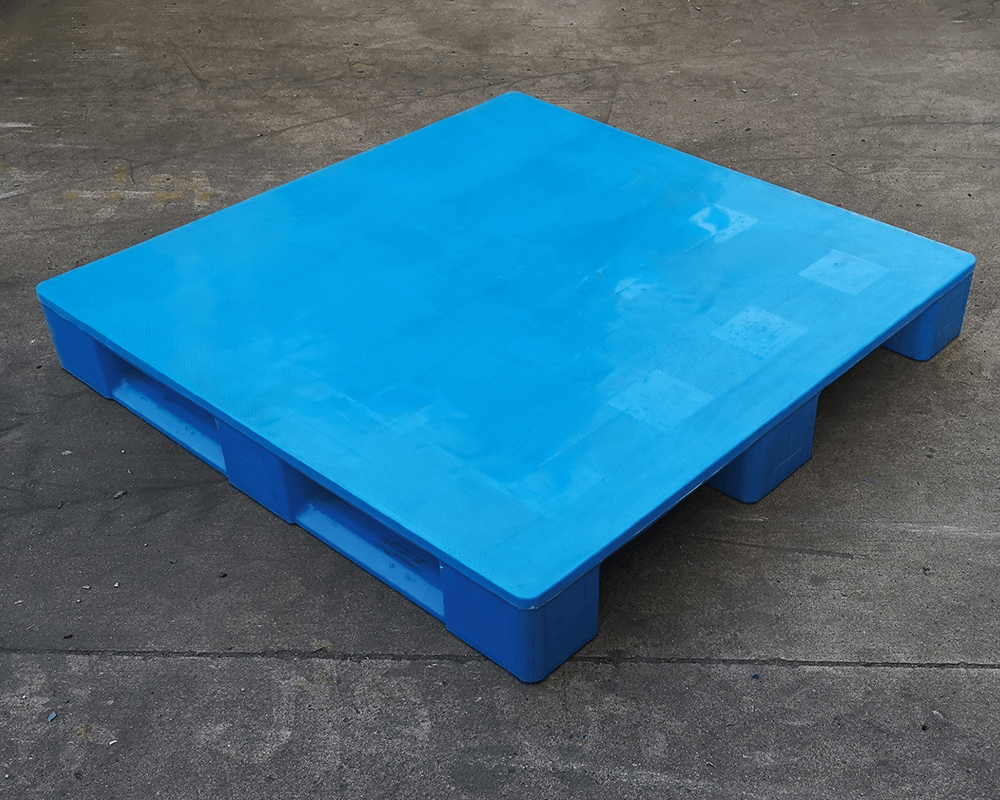

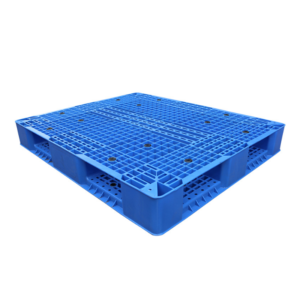

Built to support multi-layer cargo stacking in high-load environments, our stackable plastic pallets feature a 6-runner, double-face structure for enhanced load stability during high stacking. For lighter loads, 3-runner options with optional steel reinforcements are also available to meet diverse handling demands.

Built for vertical stacking, our pallets allow stable multi-layer stacking—up to 8–10 units high—maximizing vertical storage without compromising safety. This helps optimize warehouse capacity, reduce floor footprint, and streamline outbound logistics.

Lightweight yet structurally sound, these pallets minimize freight weight while maintaining durability. They are ideal for air cargo, express shipping, and e-commerce warehouses where lower tare weight directly reduces operating costs.

Our pallets are available in standard sizes such as 1200×1000 mm, 1100×1100 mm, and 48×40 inches, with load-bearing capacity from 0.5 to 4 tons—covering diverse warehouse needs from daily handling to semi-heavy-duty storage.

Equipped with 4-way forklift access, our pallets work seamlessly with manual jacks, forklifts, and reach trucks. Even when stacked 8–10 layers high with cargo, they maintain excellent stability during handling, lifting, and warehouse movement.

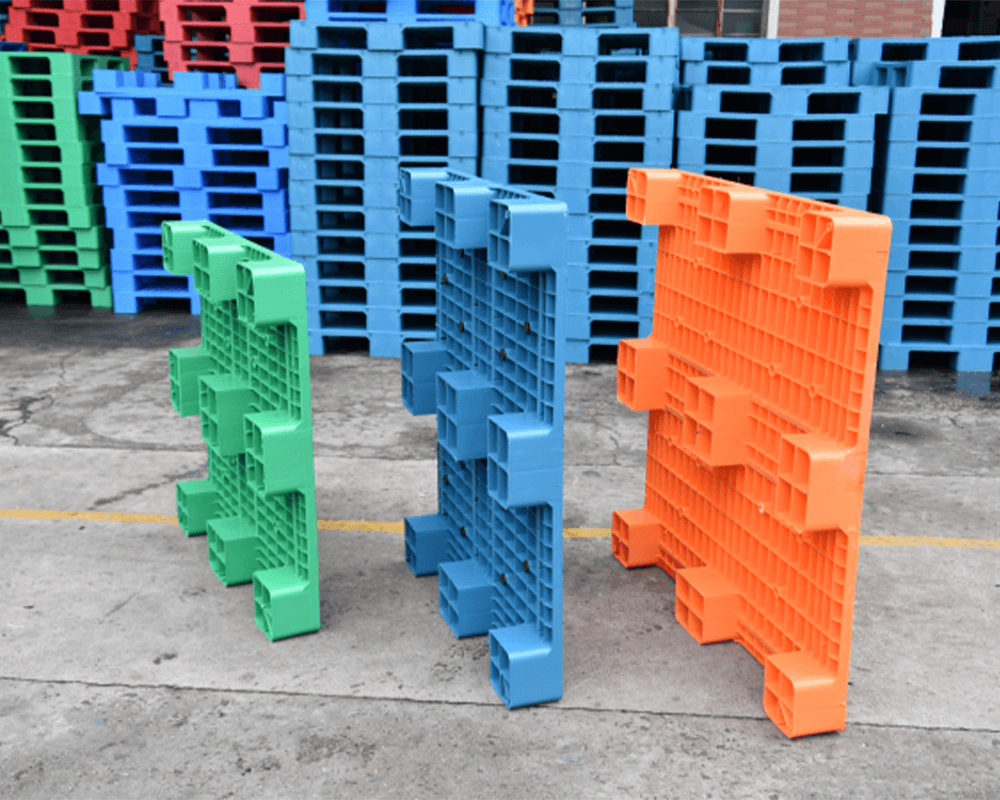

Options include one-way models for export or durable HDPE/PP pallets for multiple reuse. Custom branding, colors, anti-slip surfaces, and deck patterns are available to fit your logistics, storage, or operational branding requirements.

Crafted from HDPE or PP, these pallets have smooth, washable surfaces with optional drainage holes. Resistant to moisture and contaminants, they meet hygiene standards required in food, pharmaceutical, and cross-border export environments.

| Stackable Pallet | 6 runners / double face | ✅ | Light-duty logistics | 1–4T | Saves 50–70% return volume | Lower cost |

|---|---|---|---|---|---|---|---|

| VS | Comparison Keyword | Structure | Rack use | Application | Load capacity | Return efficiency | Unit cost |

| Rackable Pallet | 3 /6 runners + reinforcements | ✅ | Heavy-duty storage | 1–4T | Full-size return volume | Higher cost |

RELIABLE PERFORMANCE STARTS WITH RIGOROUS TESTING.

At Preface, each stackable plastic pallet undergoes a strict series of performance and durability tests to ensure it meets the demands of modern logistics. Whether for heavy-duty storage, automated handling, or export use, we validate every unit against operational stress, structural safety, and load stability.

Our in-house quality inspections include:

Drop Test

Simulates forklift accidents and edge impact during transport and warehouse handling.

Stack Load Test

Verifies stability and structural strength when stacked with 2–3 fully loaded pallets.

Sealing Test

Ensures sealed designs prevent moisture or liquid ingress under high-humidity conditions.

Air Tightness Test

Applied to specific sealed units to confirm internal air retention and structural tightness.

Size & Structure: Customize size, height, foot spacing, and choose stackable, nestable, collapsible, or fixed types.

Load & Base: Define load ratings and select 3-runner, 9-leg, or cruciform base with optional steel reinforcements.

Material & Durability: Use HDPE, PP, food-grade or recycled plastic with UV, anti-freeze, or flame-retardant options.

Color & Branding: Choose any color, anti-slip texture, and add logo by print, IML, laser, or removable label slots.

Tracking & ID: Add RFID, barcode, or QR code and enable sensor tracking for logistics or cold chain monitoring.

Compliance & Industry Fit: Eco materials with REACH, FDA, RoHS; support food, chemical, cold chain, and ASRS use.

Our standard MOQ is 200 pieces per model. However, for first-time buyers or sample evaluation, we offer flexible terms depending on the region and customization level required.

Yes. We offer full customization options including corporate colors, hot stamping or embossed logos, and optional anti-slip surfaces. Custom deck textures can be developed based on your handling needs.

These pallets are ideal for boxed goods, shrink-wrapped cargo, drums, and bulk containers that allow for stable stacking. They are commonly used in FMCG distribution, auto parts logistics, and chemical packaging.

Absolutely. Our pallets are compliant with ISPM-15 exemption for international shipping, and can be produced with materials that meet FDA, RoHS, or REACH standards upon request.

Yes, selected stackable pallet models are compatible with automated systems such as conveyors, robotic arms, and AS/RS. However, compatibility depends on strict dimensional standards—typically 1200×1000 mm or 48×40 inch with 6-runner, double-face designs. We can fine-tune pallet dimensions and base structure to meet the specific requirements of your automation line.

+86 131 7320 7232

sales29@cnplasticpallet.com

Optics Valley Software Park, Huangdao District, Qingdao City, Shandong Province, China

With over 24 years of manufacturing experience, Preface deliver over 500,000 plastic pallets annually to 40+ countries. Certified by ISO 9001 and SGS.

With over 24 years of manufacturing experience, Preface deliver over 500,000 plastic pallets annually to 40+ countries. Certified by ISO 9001 and SGS.

Contact Us Online

Receive a response within one business day. Please check your emails at “sales29@cnplasticpallet.com” to ensure timely and efficient communication.